Preparation of a Gas Sensor of Nanostructure Tin Oxide Working on the Principle of Thermoelectric Effect and Studying Its Sensitivity to Some Gases

Abstract

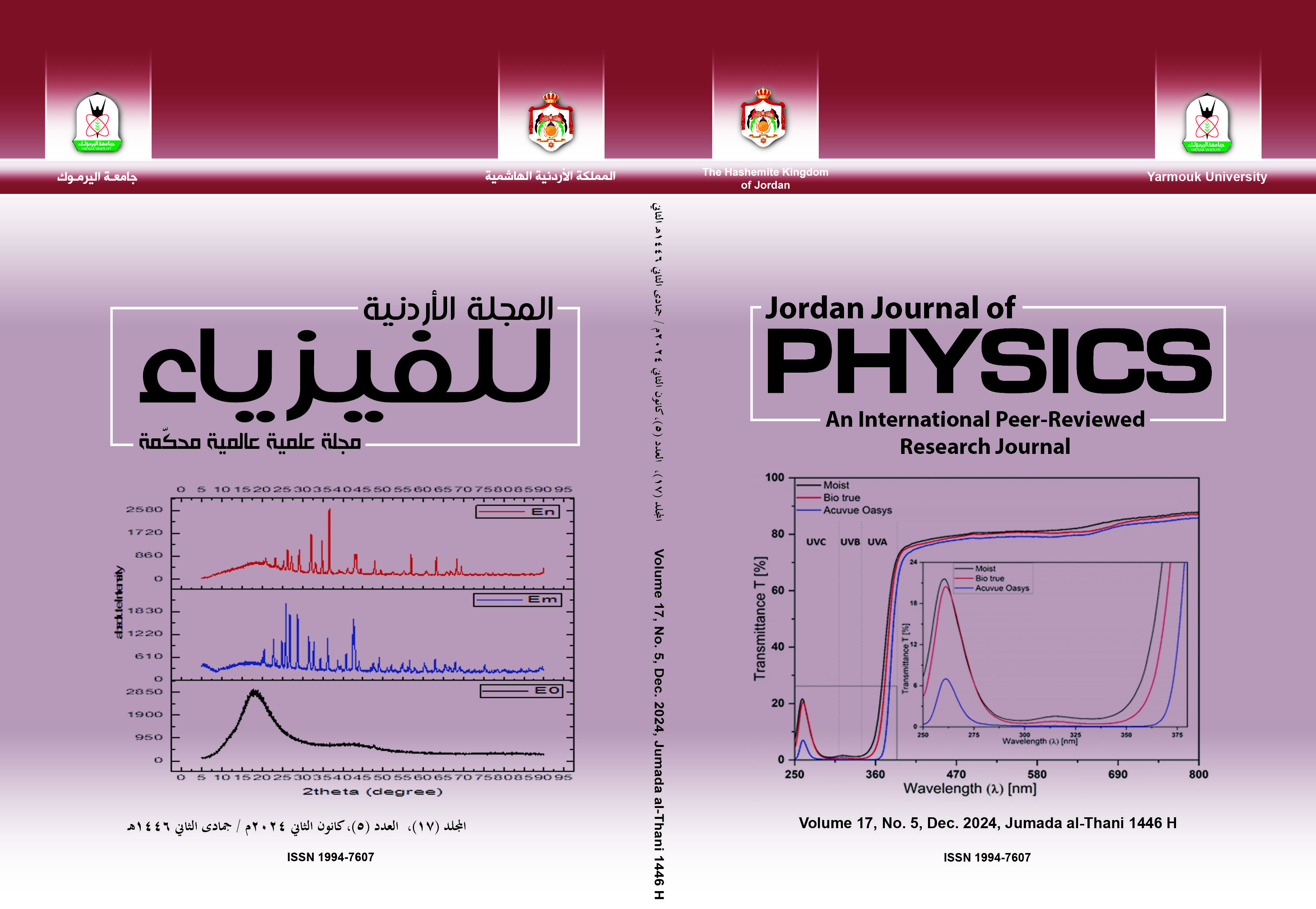

Tin oxide thin films doped with iron or copper were deposited on glass and porous alumina substrates, using co-deposition dip coating sol-gel technique. The films were doped with iron oxide at a concentration of %5. Alumina substrates were prepared by anodizing technique. Samples were sintered for 2 hours at a temperature of 600ºC. The XRD of deposited samples showed a polycrystalline structure with clear characteristic peak of SnO2 cassiterite phase. Thermoelectric effect was measured with change of temperature for the prepared samples under a low pressure of 1mbar. Seebeck coefficient for the prepared samples was measured under a low

pressure of 1mbar. Seebeck coefficient was improved when films were deposited on porous alumina. Film sensing towered H2S and H2 gases and (H2S-H2) mixture was measured as function of gas concentration and temperature. It is noted that film sensing increased with increasing gas concentration and temperature. Selectivity factor was calculated to H2S and H2 gases.

Keywords: Tin oxide; Seebeck effect; Nanostructure.