Corrosion Products Study of VVER-440 Secondary Circuit

Abstract

The variability of the properties and the composition of the corrosion products of the stainless CrNi and mild steels in dependence on the conditions (temperature, acidity, …etc.) are of such range that, in practice, it is impossible to determine the properties of the

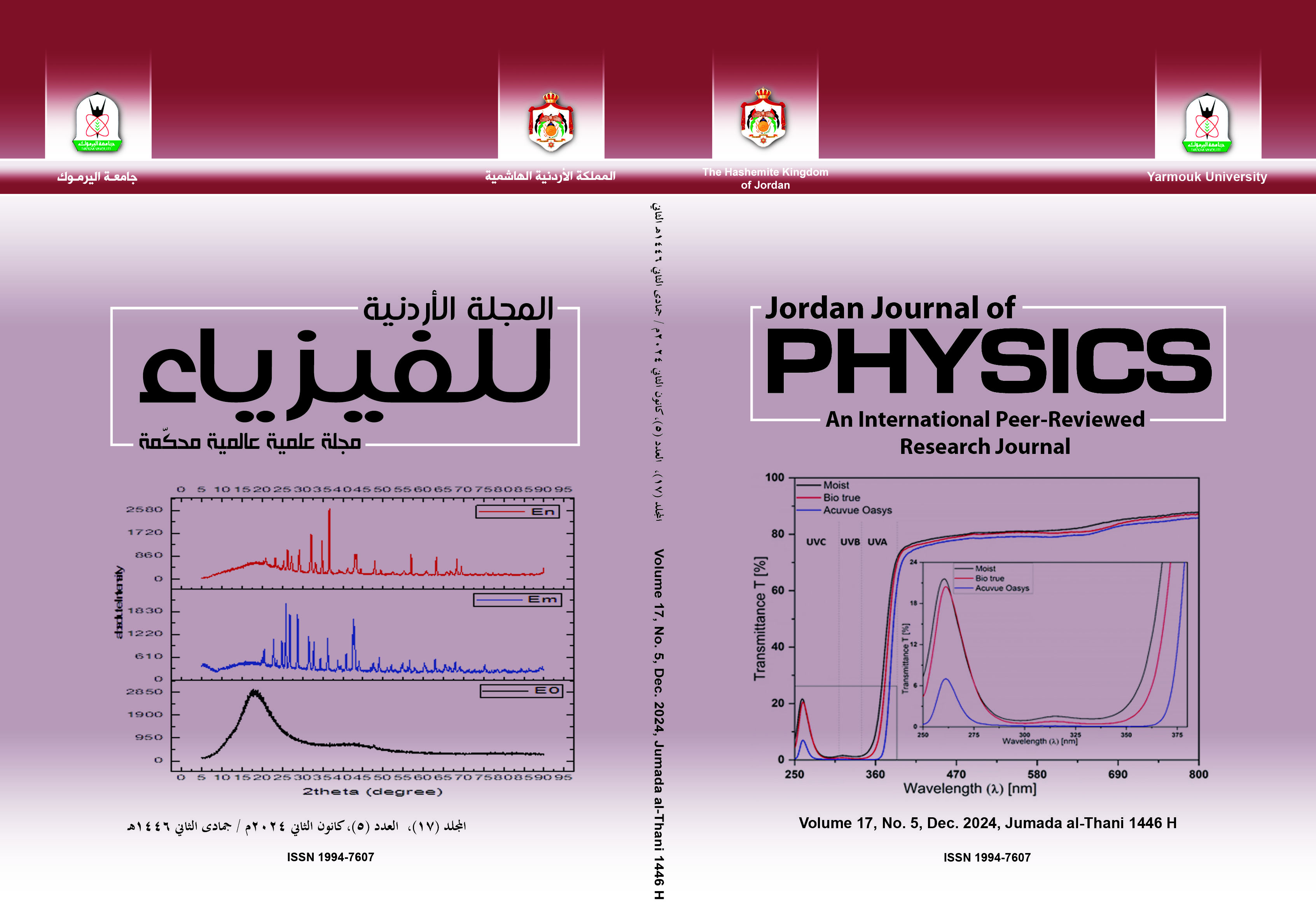

corrosion products for an actual case from the theoretical data only. Since the decontamination processes for the materials of the water-cooled reactor (VVER-440) secondary circuits are in the progress of development, it is necessary to draw the needed information by the measurement and analysis of the real specimens. The corrosion layers were separated by scraping the rust off the surface and the powder samples were studied by transmission Mössbauer spectroscopy. It should be noted that the gamma spectroscopic

measurements give no evidence of the presence of low-energy gamma radiation emitted from the samples. The57Co in Rh matrix was used as the radioactive Mössbauer source. Measured spectra were fitted using NORMOS SITE program. According to the results

obtained from Mössbauer spectra, it is possible to establish that the main component of secondary circuit’s corrosion products is magnetite Fe3O4. Next components are hematite alfa-Fe2O3 and hydroxide akagenite beta-FeOOH, which is characterized by significant

paramagnetic doublet in the middle of the spectra. The sextets corresponding to base materials (martenzite and austenite steels) were identified in all measured spectra. Corrosion distribution and phase composition in form of “corrosion maps” at steam generators as well as other secondary circuit components were created for VVER-440 nuclear power plant in Jaslovske Bohunice (Slovakia). Our study was focused on the ratio magnetite/hematite and ways for operational optimization.

Keywords: Corrosion; VVER; Mössbauer spectroscopy; NPP lifetime.