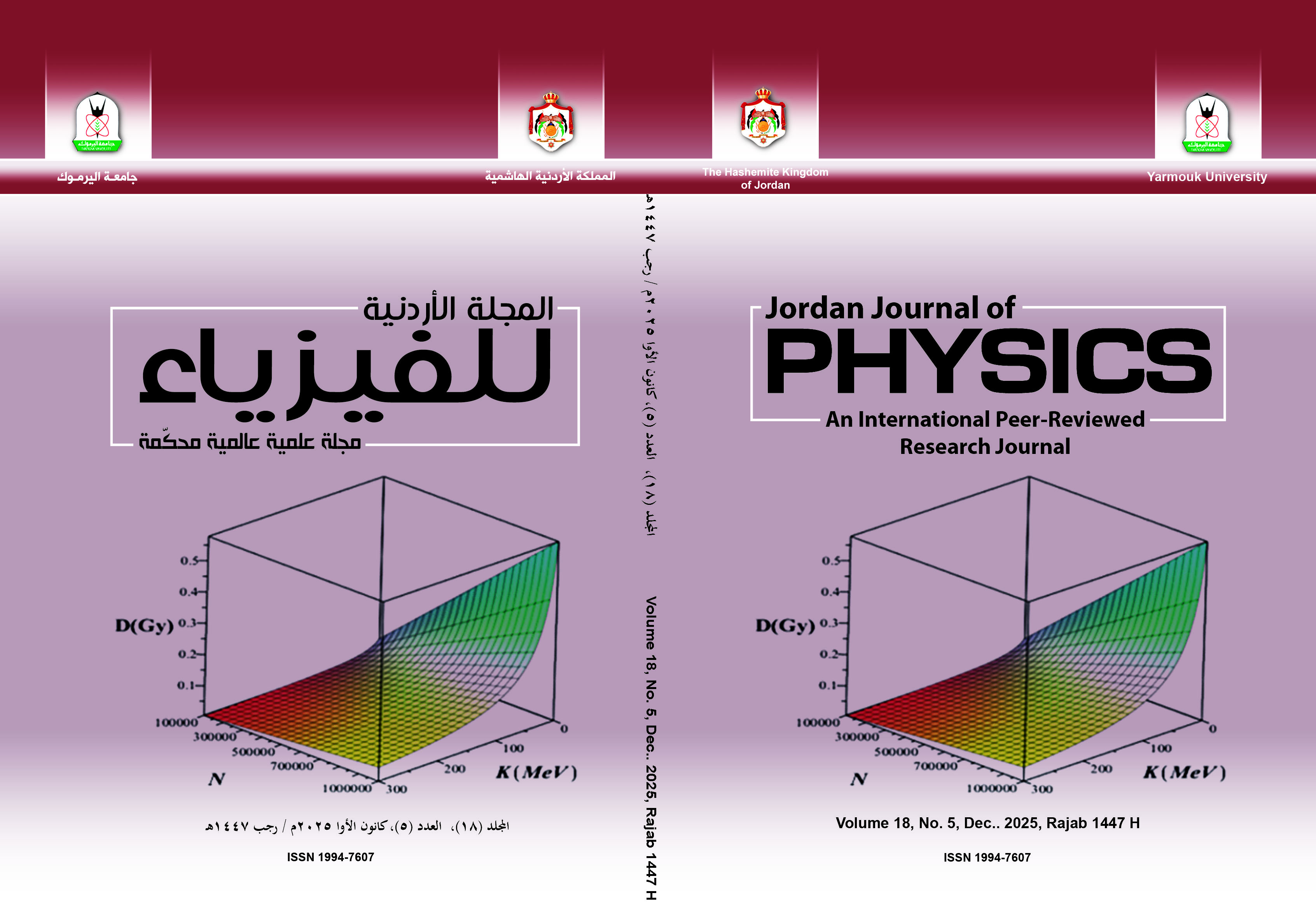

Electrospinning of PVA-PEG Blend with Various Cu2O Nanoparticle Additives: Structural and Dispersion Properties

Abstract

Abstract: This project entailed the synthesis of novel nanofibers by the electrospinning technique. The nanofibers included Poly (vinyl alcohol) (PVA) and polyethylene glycol (PEG) doped with different concentrations (0.002, 0.004, 0.006) of copper oxide (Cu2O) at room temperature. Images from the optical microscope (OM) revealed a fine and homogenous dispersion of the nanomaterials. This was corroborated by Scanning Electron Microscopy (SEM) analysis, which showed that the delicate fibers in both the polymer blend and doped samples were randomly distributed and no signs of nanoparticle aggregation were detected. Prior to the incorporation of the Cu2O additive, the nanofibers demonstrated an average diameter of 68.97 nm, while the inclusion of Cu2O at varying concentrations yielded average diameters of 64.14 nm for 0.002 g, 71.35 nm for 0.004 g, and 68.46 nm for 0.006 g. Notably, these nanofibers maintained a smooth surface morphology across all samples. The transmittance progressively decreases, starting at a value of 0.996 for the unmodified PVA-PEG blend and reducing to 0.978 as the Cu2O concentration reaches 0.006. Concurrently, the extinction coefficient demonstrates increase, rising from 0.001027 to 0.00475 with higher Cu2O content. Similarly, the real part of the dielectric constant increases from 1.4559 to 2.1044, while its imaginary part expands from 0.00247 to 0.0137. The Wemple-DiDomenico model was utilized to compute the dispersion coefficients, comprising Eo, Ed, no, M-1, and M-3.

References

Radwan, R.M., J. Phys. D. Appl. Phys. 40 (2) (2007), 374–379.

Al Asadi, S.M., Hamood, F.J., Abass, K.H., Mohammed, S.K., Hassan, I.M., Latif, D.M.A., Research Journal of Pharmacy and Technology 12 (6) (2019), 2768-2771.

Robertson, J., Materials Today 7 (2004), 46-52.

Devangamath, S.S., Lobo, B., Masti, S.P., et al., J. Mater. Sci. Mater. Electron. 31 (2020), 2904–2917.

Beachley, V., Wen, X., Prog. Polym. Sci. 35 (2010), 868.

Shenoy, K.A., M.Sc. Thesis, Department of Mechanical Engineering, Wichita State University (2008).

Ben Doudou, B., Vivet, A., Chen, J., Laachachi, A., Falher, T., Poilâne, C., J. Polym. Res. 21 (4) (2014), 1–9.

Abdali, K., Al-Bermany, E., Abass, K.H., J. Polym. Res. 30 (4) (2023), 138.

Abu-Zied, B.M., Asiri, M.A., Int. J. Electrochem. Sci. 10 (6) (2015), 4873-4887.

Chieng, B.W., Ibrahim, N.A., Yunus, W.M.Z.W., Hussein, M.Z., Polymers 6 (2014), 93-104.

Abass, K.H., Hamed, A., J. Green Eng. 10 (7) (2020), 4166–4176.

Sawant, S.S., Bhagwat, A.D., Mahajan, C.M., J. Nano- Electron. Phys. 8 (1) (2016), 01035(1-5).

Jayathilaka, C., Kumara, L.S.R., Ohara, K., Song, C., Kohara, S., Sakata, O., Siripala, W., Jayanetti, S., Crystals 10 (2020), 609.

Isah, K.U., Bakeko, M., Ahmadu, U., Uno, U.E., Kimpa, M.I., Yabagi, J.A., IOSR J. Appl. Phys. 3 (2) (2013), 61-66.

Gevorkyan, V.A., Reymers, A.E., Nersesyan, M.N., Arzakantsyan, M.A., Int. Symp. Optics and Its Applications (OPTICS2011) 350 (2012), 012027 (1-6).

Umar, M., Swinkels, M.Y., De Luca, M., Fasolato, C., Moser, L., Gadea, G., Marot, L., Glatzel, T., Zardo, I., Thin Solid Films 732 (2021), 138763(1-11).

Abbas, A., Abass, K.H., Mater. Today: Proc. 60 (2022), 1402–1408.

Wei, H.M., Gong, H.B., Chen, L., Zi, M., Cao, B.Q., J. Phys. Chem. C 116 (19) (2012), 10510–10515.

Bai, Y., Yang, T., Gu, Q., Cheng, G., Zheng, R., Powder Technol. 227 (2012), 35–42.

Tuama, A.N., Abass, K.H., Bin Agam, M.A., Int. J. Nanoelectron. Mater. 13 (3) (2020), 601-614.

Salek, G., Tenailleau, C., Dufour, P., Guillemet-Fritsch, S., Thin Solid Films 589 (2015), 872-876.

Lupan, O., Cretu, V., Postica, V., et al., Sens. Actuators B Chem. 224 (2016), 434–448.

Lee, W-J., Wang, X-J., Coatings 11 (2021), 864, 1-13.

Siol, S., Hellmann, C.J., Tilley, S.D., et al., ACS Appl. Mater. Interfaces 8 (33) (2016), 21824–21831.

Alkelaby, A.S., Abass, K.H., Mubarak, T.H., et al., J. Glob. Pharma Technol. 11 (4) (2019), 347-352.

Kadhim, R.G., World Sci. News 30 (14) (2016).

Jose, J., Al-Harthi, M.A., AlMa'adeed, M.A.A., Dakua, J.B., De, S.K., J. Appl. Polym. Sci. 132 (16) (2015).

Schubert, D.W., Macromol. Theory Simul. 28 (2019), 1900006.

Wang, Q., et al., Anal. Chim. 125–132 (2018).

Jia, Y.T., Gong, J., Gu, X.H., Kim, H.Y., Dong, J., Shen, X.Y., Carbohydr. Polym. 67 (2007), 403-409.

Rasheed, M.H., Hashim, F.S., Abass, K.H., Int. J. Nanosci. 22 (3) (2023).

Qader, K.Y., Ghazi, R.A., Jabbar, A.M., Abass, K.H., Chiad, S.S., J. Green Eng. 10 (10) (2020), 7387-7398.

Abass, K.H., Latif, D.M.A., Int. J. ChemTech Res. 9 (9) (2016), 332-338.

Wemple, S.H., DiDomenico, M., Phys. Rev. B 3 (4) (1971).

Mohammed, H.R.A., Al-Ogaili, A.O.M., Abass, K.H., Mater. Today: Proc. 80 (2023), 2396-3304.

Alkelaby, A.S., Ahmadi, M.T., Esmaeili, A., Sedghi, H., Abass, K.H., Polym. Bull. 81 (2024), 17377–17391.

Sakhil, M.D., Shaban, Z.M., Sharba, K.S., Habubi, N.F., Abass, K.H., Chiad, S.S., Alkelaby, A.S., NeuroQuantology 18 (5) (2020), 56-61.

Chiad, S.S., Alkelaby, A.S., Sharba, K.S., J. Glob. Pharma Technol. 11 (7) (2019), 662-665.

Da Silva, M.A., Crawford, A., Mundy, J., Martins, A., Araújo, J.V., Hatton, P.V., Reis, R.L., Neves, N.M., Tissue Eng. Part A 15 (2) (2009), 377-385.

Abass, K.H., Obaid, N.H., J. Phys. Conf. Ser. 1294 (2) (2019).

Tuama, A.N., Abass, K.H., Bin Agam, M.A., Optik 247 (2021), 167980. DOI: 10.1016/j.ijleo.2021.167980.

Alkelaby, A.S., Abass, K.H., Mubarak, T.H., Habubi, N.F., Chiad, S.S., Al-Baidhany, I., J. Glob. Pharma Technol. 11 (4) (2019), 347-352.

Kadhim, R.G., World Sci. News 30 (14) (2016).

Jose, J., Al-Harthi, M.A., AlMa'adeed, M.A.A., Dakua, J.B., De, S.K., J. Appl. Polym. Sci. 132 (16) (2015).

Al-Shawabkeh, A.F., Elimat, Z.M., Abushgair, K.N., J. Thermoplast. Compos. Mater. 36 (2023), 899–915.

Sharba, K.S., Alkelaby, A.S., Sakhil, M.D., Abass, K.H., Habubi, N.F., Chiad, S.S., NeuroQuantology 18 (3) (2020), 66-73.

Zbala, A.A.K., Al-Ogaili, A.O.M., Abass, K.H., NeuroQuantology 20 (2) (2022), 62–68.

Abass, K.H., Latif, D.M.A., Int. J. ChemTech Res. 9 (9) (2016), 332-338.

Wemple, S.H., DiDomenico, M., Phys. Rev. B 3 (4) (1971).

Mohammed, H.R.A., Al-Ogaili, A.O.M., Abass, K.H., Mater. Today: Proc. 80 (2023), 2396-3304.

Alkelaby, A.S., Ahmadi, M.T., Esmaeili, A., Sedghi, H., Abass, K.H., Polym. Bull. 81 (2024), 17377–17391.

Sakhil, M.D., Shaban, Z.M., Sharba, K.S., Habubi, N.F., Abass, K.H., Chiad, S.S., Alkelaby, A.S., NeuroQuantology 18 (5) (2020), 56-61.

Chiad, S.S., Alkelaby, A.S., Sharba, K.S., J. Glob. Pharma Technol. 11 (7) (2019), 662-665.